New advanced materials - key to the green transition

New advanced materials are a crucial part to succeed in the green transition and to strengthen Swedish competitiveness. Vinnova is now financing several exciting project in the development of graphene - an extremely thin and strong material with many unique properties.

To succeed with the green transition and develop everything from high-tech products to sustainable textiles and packaging, new advanced materials are needed. Traditional materials are the basis for a large part of Sweden's basic industry and the development of new advanced materials is now one of the dominant areas in the Swedish deeptech ecosystem.

2D materials, bio-based materials, polymers and composite materials are being developed to, for example, save energy, be lighter, stronger and more recyclable. They are used for the development of high-tech products and applications, such as communication technology, batteries, wind turbines, solar cells and electric motors as well as textiles and packaging. Advanced materials are also on the EU Commission's lists of priority key technologies for Europe's technological independence and of critical technologies for Europe's economic security.

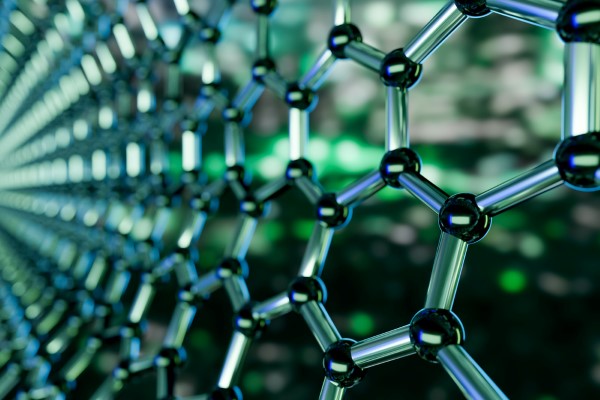

Graphene - super material with multi-functionality

One of the most interesting materials deemed to have enormous potential is graphene, whose discovery was awarded the Nobel Prize in Physics in 2010. Carbon-based graphene is a so-called 2D material that is extremely thin, yet extremely strong, bendable, conducts current and can withstand very high temperatures. In addition, it is almost transparent. It comes in many different forms and qualities and has a multitude of potential uses.

- Sweden is far ahead in research into graphene and 2D materials and not least in exploring industrial applications. Swedish companies are also successful in producing graphene and refining graphene materials. Many property improvements are aimed at the green transition, such as battery and solar cell development, as well as creating more energy-efficient products and less material use, says Fredrik Sahlén, Senior research leader in electrical insulation systems at ABB and chairman of the strategic innovation program SIO Grafen.

Swedish companies are also successful in producing graphene and refining graphene materials.

Over the past decade, the innovation program has played a central role in the development of graphene in Sweden.

- SIO Grafen has created an ecosystem of graphene stakeholders in Sweden, which enables meetings between academia, research institutes and companies in the entire value chain, from graphene manufacturers to end users. A success factor has been that the program has supported project in different maturity phases; feasibility studies, innovation and demonstrator projects, says Fredrik Sahlén.

He believes that a basic prerequisite for graphene and other new advanced materials to reach wider industrial use is that the materials, in addition to environmental improvements, either add new functionalities or cost savings.

- In order for the material to be used industrially, it is important that the material supply is stable, the quality is predictable and reliable and that the price is reasonable. In this context, it is also important that international standards are developed and that the safety of material handling is ensured.

Vinnova finances five new graphene project

Vinnova is now financing five more graphene project within SIO Grafen. One of the funded projects is run by the medtech company Wellspect together with Mittuniversitetet, Chalmers technical university college and Cobolt AB. The goal is to develop graphene surface layers for catheters, which can provide effective protection against bacteria to reduce the risk of urinary tract infections.

- Infections caused by the use of invasive medical devices are a major problem in healthcare. An antibacterial surface based on graphene has several advantages over other alternatives as it has a very high effect and is sustainable both in terms of the risk of resistance development and the environment, says Martin Lovmar, responsible for research-and development at Wellspect.

"Development of new materials takes a long time"

CelluXtreme is a materials startup that is based on a research breakthrough within Wallenberg Wood Science at KTH, a spinning technology that enables the production of very strong and stiff fibers from pure cellulose. With that as a base, the company is developing a new composite concept. Composite materials are used today as lightweight materials in, for example, the manufacture of aircraft parts, sports equipment, medical equipment and wind turbine blades where very light but rigid components are needed.

- Our objective is to develop a unique high-performance and bio-based lightweight material that responds to society's increasing eligibility requirements for sustainable production and consumption of materials and products. Bio-based materials are important as more environmentally friendly substitutes in both manufacturing and recycling, but can also have completely new properties and possibilities, and that's when it becomes really competitive, says CEO Anna Wiberg.

In its first development phase, CelluXtreme was part of the Vinnova program Innovative startups and in autumn 2023 received funding within the call for proposals Acceleration of deeptech companies through which the company can work on scaling up to pilot projects.

Anna Wiberg has solid experience in leading positions in the innovation system for the development of advanced bio-based materials and emphasizes how important funds for research and innovation and a strong innovation system are for the development of new material concepts.

Development of new materials takes a long time and is very different from the development of digital solutions, which are easier to test and then implement.

- Development of new materials takes a long time and is very different from the development of digital solutions, which are easier to test and then implement. When a new material platform is to be developed, it is not only necessary to test the properties of the material, but also how it reacts when producing larger quantities and how to solve mass production. There, the soft funds, which give a chance to accelerate deeptech solutions, are so incredibly important in order to be able to bring in private financiers in the next step, says Anna Wiberg.

Last updated 21 February 2024

Page statistics